This detailed guide helps with estimating rehab costs accurately for a number of common home improvement items in your house flipping project.

The cost to renovate your house will of course vary based on the scope of work you intend to do. However, by comparing your renovation plan to the typical rehab costs, you can generate an accurate repair estimate, and that is the aim of this guide.

What is the cost to rehab a house?

Accurate construction cost estimates are some of the most difficult costs for new investors to come up with when estimating a real estate rehab project. There are simply so many variables to account for that generating an accurate estimate can be a daunting task.

Many try to find contractors to get a rehab estimate for a flip. However, it’s difficult to find a general contractor to give you estimates without guaranteeing continual business, or paying for an estimate on every property you want to put an offer on.

Given that contractors are generally out of the equation for many new investors, I put together this guide to enable you to estimate your own rehab costs. While you might not always be able to generate fully accurate estimates, having a guide to look to for reference will help you to get somewhere in the right area. The more experience you get, the more accurate your investment estimates will become.

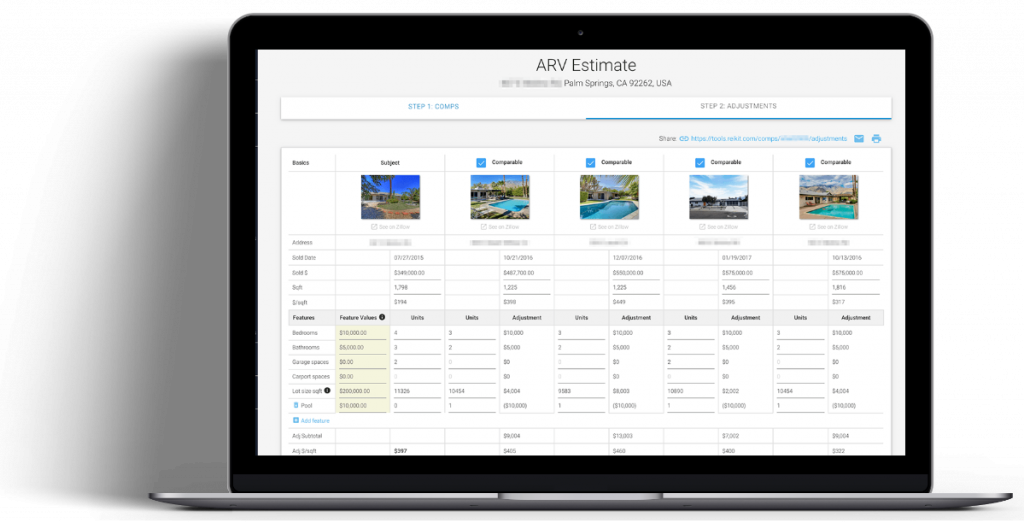

In addition to using this guide, you can use the REIkit real estate rehab cost estimator tool to help you estimate the costs of a rehab.

This online rehab estimator calculator uses regularly updated data from one of the oldest and most respected construction cost book companies around.

They provide us with nationwide construction costs indexed down to a zip code. Simply select an item and the quantity to be added to an itemized list that you can then use for comparing contractor bids when you can get contractors to come out

First, however, I want to briefly talk about a trap that investors fall into when starting out: trying to establish a price per square foot for estimating repair costs.

Why you shouldn’t estimate the cost of rehabbing a house using price per square foot

Many new investors try to take shortcuts and estimate the average cost of rehabbing a house on a per sq ft basis.

Unless you have done quite a few rehabs in the same neighborhood on the same types of properties, in most cases this doesn’t work on a number of levels.

First: Ask any contractor whether they can give you a ballpark estimate on how much to rehab a house sight unseen, and it’s almost guaranteed that they will flat out refuse.

That’s because every single house, and yes, even identical houses, can have substantially different rehab items that must be taken care of.

You just cannot reasonably estimate how much it will cost to rehab a property without identifying each repair and a breakdown of the individual components.

It simply doesn’t make sense to estimate a cost without knowing the factors that go into that cost. Houses vary so much in their needs that you can’t just base an estimate on something arbitrary like square feet.

Second: The pricing of these components is largely dependent on your local market, where material pricing is affected by local taxes, labor pricing by legal requirements, supply and demand forces, and choice of finishings.

Given this, not surprisingly if you ask a hundred investors what their average price per square foot is, you’ll get a hundred different answers.

So, wait — if you shouldn’t use average price per square foot, and you have to look at each repair or system individually, how exactly do you estimate repair costs?

How to estimate rehab costs

Simply put, it will take experience, time, and practice. Get out there and look at as many properties as you can find. Use your camera phone to carefully film the property condition, and then return to this list to create your rough estimate.

The best way to go about calculating costs is to evaluate factors on an individual basis. Use each component of your rehab plan to generate a new part of your investment. This guide will provide you with a general way to estimate the most common aspects of a rehab plan.

The construction items and systems shown below is not an exhaustive list, but it should give you a pretty good idea of what to expect when trying to estimate the cost to rehab a house.

Again, the pricing of these components is largely dependent on your local market, where material pricing is affected by local taxes, and labor pricing by legal requirements, supply and demand forces, and choice of finishings. This is also why it is helpful to use our real estate rehab cost estimator to understand the local pricing of those components.

As a result, do know that pricing given in this guide below is a very rough average, so they should be used only as a starting point and looked at as a way to help you evaluate the competitiveness of your contractor bids. In reality, this guide should be supplemented by your personal experience and your knowledge of your local market.

So, let’s go into detail of some of the considerations of each of these house rehab costs, starting with the demo and following with the haul away of materials.

Rehab Construction Costs Contingency

Demolition and Haulaway

Demolition

Demolition costs can vary widely depending on the type of material being removed. Typically, the harder to remove, and heavier, the more it costs.

For example, the removal of tacked carpet can cost a crew as little as $1.40/SY, and on the other hand, glued hardwood can cost as much as $25/SY to remove. So first, evaluate how difficult it will be to remove your components, and then make an estimate of cost.

Haulaway

Hauling costs are divided into hauling, and disposal fees. For hauling you can expect to pay starting at $230 + $50/ton for a 40CY bin, with disposal fees at the dump around $75/ton.

The weight of your waste makes a big difference when estimating the cost of hauling and disposal. For example, a 1CY of waste of wood weighs about 0.25 ton, whereas 1CY of concrete can weigh 5X more at about 1.25 tons. Depending on the extent of your demolition, you may need to haul the bin away up to 5 times for 1000 SF house.

For the demo and haul away of a complete building, where the structure remains, you can expect to pay around $5/SF, which includes haul away, but not disposal fees.

As you can see, hauling costs vary mainly on size of the project and weight of the materials being hauled.

Next, let’s take a look at materials and costs for items on the exterior of the property.

Outside

Siding & Trim

Many older homes have wood siding called clapboard. This can be fixed with wood filler and painted about every 10 years, or replaced. Other forms of siding include aluminum, asbestos, vinyl, as well as stucco. Aluminum siding can be easily damaged, is harder to repair, and is harder to paint than wood siding. Asbestos siding is normally not dangerous and generally non-friable, and can be easily painted or covered up with another type of siding, but this may be undesirable due to disclosure laws. Vinyl siding has nearly replaced the others as it lasts a long time and doesn’t need to be painted.

Siding replacement cost estimation: When measuring for siding, one would ignore wall openings, and measure the wall area to be repaired or replaced. You can expect a typical installation of vinyl siding to cost between $340-$650/CSF of wall area depending on the quality of siding. CSF refers to 100 square feet. As you can see, it varies mainly on the material being used and the amount of area covered.

Paint

There are a number of considerations when painting the outside of a house such as the surface to paint, and the height of the building. Before doing so, one should consider whether it is necessary to paint at all, and whether a simple power wash will achieve the same effect.

Estimate painting costs: A typical cost to repaint a house exterior with one coat of paint at 2 painter hours and 1gallon of paint per 100 SF (1 CSF) can cost around $160/CSF, or $1.60/SF. You will then need to add costs for height, as well as painting trim. For example: for heights of 8ft-13ft you would add 30% to the cost. For heights of 13-17ft you may add 60% to the cost of painting. This is because it becomes more labor intensive the higher you need to paint.

Windows & Doors

Windows

Replacing windows can increase the resale value of your property, however it can be fairly expensive if you cannot find a stock window with standard measurements.

For example, if your window openings fit standard vinyl windows, then you can expect to pay between $275 and $400 depending on the size of the opening and glazing options. On the other hand, creating custom vinyl windows to match a non-standard opening can double those prices.

So be sure to determine your window estimates based on whether you need to order them custom or whether a stock size will fit.

Doors

Exterior doors can cost between $200 for a basic slab door, to $2,000 for a stylish Oak or Mahogany entryway. You can expect to pay about $1,500 to cut a wall opening and install a slab door.

Interior doors are much less expensive and typically range between $100 and $500 depending on material, style, and size.

Estimate your costs for door installation based on the cost of the door and the installation required.

Roofing

Life expectancy

The life expectancy of roofing depends on the type of roofing installed. A typical 3-tab shingle lasts about 20 years, architectural shingle can last 45 years, and tile up to 150 years. Very often part of the need for a new roof is a result of the deterioration of roof decking. Additionally, with roofing that is layered on top of older roofing, reduces life expectancy by 10-15 years.

Measurement

To measure a flat roof, just divide the area into rectangles, calculate the area of each, and add up the total. To calculate the roof surface of a sloping roof accurately, you have to multiply the rafter lengths by the width of each pitch. However, if the roof pitch is no more than 5 in 12, a simple rule of thumb will yield nearly the same result in a fraction of the time:

Multiply the length and width of the building, including eaves and overhang. Divide by 100 to find the number of roofing “squares.” Then add 10 percent for a gable roof, 15 percent for a hip roof and 20 percent for a roof with dormers. A square is equivalent to 100 square feet.

Costs

Roofing tear off can cost between $50/SQ for asphalt to $100/SQ for tile, and this cost doesn’t cover haul away.

A new shingle roof can cost from $230/SQ for a basic 20 year shingle, to almost $400/SQ for fire rated and wind resistant 40 year shingles. Clay tile starts at almost $800/SQ, and red slate can run up to $3,600/SQ.

The main costs you need to account for are therefore removal costs, installation costs, and cost of the shingles.

Decks and Pools

Basic deck

A standard post and beam wood deck uses pressure treated framing lumber with 4″ x 6″ posts set in concrete. A basic estimate would include concrete, pressure treated posts, beams, joists 12″ on center, unfinished deck plank, galvanized hardware, fasteners, 4′ wide stairs from deck level to ground level, 36″ high railing with balusters 4″ on center and stair rail.

Costs

Using pressure treated planks would start at $34/SF up to $60/SF for Edeck material. The main variation here is in the material used.

Pool considerations

In-ground pools can require re-plastering about every 5-10 years. However, due to it’s expense, it is rarely done by homeowners, which means that you will likely need to perform this maintenance.

Costs

The cost to prep the pool for plastering is around $20/LF of pool perimeter, and the cost to re-plaster starts at about $60/LF of pool perimeter.

The interior of the property, which I go over in this next section, can be the most challenging due to the number of hidden elements involved.

Inside

The interior of the property, which I go over in this next section, can be the most challenging to estimate, due to the number of hidden elements involved. Learning to expect and account for these elements is crucial in your accurate estimation, and they will be identified in this section.

Paint

Painting the inside of the house is more expensive than the outside, because it requires about 30% more time. Typical painting costs are per 100 square feet of floor for roller and brush application of a single coat to walls and ceilings in all rooms of an occupied dwelling, including bathrooms and closets. This does not include the cost of coating cabinets, trim, doors, and window trim. It does include minimum surface preparation, spackle of minor defects in wallboard or plaster, masking of adjacent surfaces and priming of stained or discolored surfaces.

Costs

Estimate painting costs: For 3 painter-hours and 1 gallon of paint per 100 square feet of floor you should expect to pay about $230. In calculating this time, you should include the extra work required to complete the factors identified above, and the extra difficulties of painting inside.

Drywall Walls, Ceilings

Adding drywall labor includes cutting board around electrical boxes and obstacles, installing on wall studs or ceiling joists 8′ to 12′ above floor level, joint tape, three coats of joint compound and finish sanding. Material includes 1/2 gallon of premixed joint compound per 100 square feet, 38 linear feet of

2″ perforated joint tape per 100 square feet, 1/2 pound of drywall screws per 100 square feet and 10% waste.

Costs

Drywall costs estimation: Typically you would use 3/8 inch board on ceilings, and ½ inch for walls. You should expect to pay about $2/SF for ceilings, and $1.80/SF for walls. This is assuming typical labor and drywall costs.

Floors

Some types of floor cover are more durable than others. Vinyl lasts longer than carpet. Ceramic tile lasts longer than wood block or strip flooring. All floor cover requires a base that’s structurally sound, clean, level (to 1/4″ per 10′ span) and dry (moisture content of the subfloor should not exceed 13 percent). Concrete makes a good base, assuming the surface is smooth and incorporates a good vapor barrier. Untempered hardboard, plywood, and particleboard also make a good base for flooring. Use either 1/4″- or 3/8″-thick sheets. Underlayment needs a 1/32″ gap at the edges and the ends to allow for expansion.

Wood

If a wood floor is smooth and free of large cracks, refinishing may put the floor back in like-new condition. Most hardwood floors can be sanded and refinished several times.

Costs

Floor sanding costs can start at $61/CSF. Most of the installation cost of wood flooring is in the material, for which you can expect to pay between $3.50 for unfinished oak, to $15 and beyond for wide plank hardwood. Most of the variation in wood flooring will come from the type of wood that you purchase.

Ceramic tile

Ceramic tile can be set in either mortar (thin-set or thick set) or applied with adhesive. Adhesive is more convenient because no mixing is required, though cleanup takes a little longer. Tile is set on backerboard, which is cement board reinforced with polymer-coated glass mesh.

Costs

Tile cost estimation: Setting tile in adhesive can start above $7/SF not including the cost of the tile itself. Doing so in thinset can start above $14/SF. The cost of the tile itself is also variable between styles and quality between $1.50-$15 and beyond for travertine. So generally, your estimation will be based on cost of the tile and area covered.

Carpet

Carpeting can be installed directly over an existing hardwood floor, assuming any voids have been filled and the surface isn’t loose. The installation of carpet includes sweeping a prepared surface, setting carpet tack strip, rebond pad, unrolling 12′- to 15′-wide carpet, measuring, marking, cutting, trimming one edge, hot melt tape on seams and disposal of debris.

Costs

For a standard quality carpet, you can expect to pay around $50/SY, and up to $115/SY for heavy traffic wool. The cost really depends on the the type of carpet that you are wanting to install.

Kitchens

Cabinets

There are a number of options for improving kitchen cabinets, starting from washing, to painting, refacing, and replacement.

Estimation Rules of Thumb

When replacing cabinetry, there is a quick rule of thumb to estimate cabinet and counter space in a home. Figures are in linear feet of counter or cabinet face per thousand square feet of floor in the living area (everything under the roof except the garage, soffit, patio and porch). Allow a little more counter and cabinet space in a small home (under 1,200 square feet). A very large home (over 4,000 square feet) may need less space. Measure linear feet of counter at the front or back edge, whichever is shorter.

- Base cabinet: 7 linear feet per 1,000 square feet of living area

- Wall cabinet: 6 linear feet per 1,000 square feet of living area

- Drawer base cabinet: 1 per 10 linear feet of base cabinet

Cost considerations

Cabinets are like furniture. Prices vary widely. For example, a drawer with hard- wood rails, plywood bottom and dovetail joints will cost considerably more than a particleboard drawer with stapled butt joints. Better-quality custom and semi- custom cabinets are made from 3/4″ or 1/2″ furniture-grade plywood covered with hardwood veneer. Drawers have full-extension roller hardware. Less-expensive cabinets are made from 3/8″ or 1/2″ particleboard, usually with a melamine coat- ing.

“Ready to assemble” cabinets cost the least and are sold primarily in do-it-yourself outlets. Options are limited and units require about an hour of assembly before they are ready to install.

Countertops

Estimation Rules of Thumb

The rule of thumb for estimating countertop needs in a house is:

- Counter: 8 linear feet per 1,000 square feet of living area

- Counter width and height: 25″ wide x 36″ high

Costs

Similar to cabinets, countertops come in many varieties in materials, from laminate starting at an installed cost of about $30/LF to a variety of stones exceeding $100/SF. The cost of your countertop will depend greatly on the type of counter you purchase.

Other Considerations

Extensive kitchen remodeling will usually require HVAC work such as moving duct, registers, grilles, hydronic piping or radiators. Consider also the cost of patching walls or ceilings after HVAC materials have been moved or added. Figure a half-day of work ($150) as the minimum charge for drywall hanging, taping and finishing.

Bathrooms

There are two types of bathroom jobs. The first simply makes better use of the available space. The second is adding space, either by enlarging an existing bathroom or by adding an entirely new bathroom. Both types will be expensive when calculated on the basis of cost per square foot of floor.

A good bathroom plan minimizes plumbing and electrical runs and locates plumbing fixtures on one wall. This arrangement allows the fixtures to share a common waste line and roof vent.

The construction costs involved in bathroom renovations include running waste lines, service lines, electric, installing bathtubs and showers, shoring up joists under bathtubs, installing vanities, and toilets, as well as tiling work both on the floor and walls.

As you can see, bathroom work varies greatly. Therefore, it is important to accurately outline every aspect of your project in order to get an accurate estimation of your rehab expenses.

Costs

The cost to install a standard enameled steel bathtub, not including connections, can be between $215-$360. Tub wall kits installed can run from $250-$750 installed. Faucet installations can cost $110 to well over $1000 depending on the fixtures used.

The setting of a toilet can start at $120 for a basic white toilet. A pedestal lavatory installation can also start at $120 for a basic model, and exceed thousands when replaced with furniture quality cabinetry and stone counters and sinks.

Tiling costs are similar to flooring tiling, and again largely depend on the materials used.

Plumbing

Plumbing and HVAC subcontractors usually quote the total installed prices only, without listing material and labor costs separately, so we don’t have good average data on this. However, there are a few jobs that are pretty common, and they can be grouped into the following categories:

Service upgrade

The upgrade of galvanized water pipe with copper pipe includes fittings and pipe clips using Type M copper pipe with soft soldered joints. This can be costed starting at $7-$12/LF.

Sewer

The drainage system consists of sewer laterals, drainage pipes and vents. It’s common for pipes in older homes to break or become clogged. Older homes have cast iron drain lines, which rust out after about 70 years. In some cases, the pipe diameter will be less than required by current codes. If you see cast iron and perform any plumbing, codes may require you to update the drain as well.

Removing and replacing cast iron drain, waste and vent pipe (DWV) with ABS pipe including fittings and 4 inch ABS plastic pipe with solvent weld joints is about $12-$22/LF.

Water heater

The installation of a gas water heater is also a common plumbing requirement. A gas water heater installation includes temperature and pressure relief valve, pipe connection labor. Costs do not include adding a flue, water and gas pipe, fitting materials and gas permit costs if required. For a basic 30-gallon water heater expect to pay between $550 and $930.

HVAC

As with the above section, there are a few jobs that are pretty common in HVAC repair. The following are some rules for accurately estimating the costs of these jobs:

Forced air heating

A common update is to add forced air heating and cooling to an older home. The Btu capacity of a residential heating system depends on climate, window size and orientation, insulation and square footage to be heated.

Estimating needs

For cost estimating purposes, there’s an easy way to calculate the Btu capacity of the furnace needed. Multiply the square feet of heated floor area by 53; then round up to the next larger furnace size. For example, to size a furnace for a 2,000 square foot home:

- 2,000 times 53 equals 106,000. The next larger furnace size is 125,000 Btu.

Work required

The installation of a 125,000 Btu gas fired furnace includes duct on interior walls including a humidifier, filter, 5 to 8 galvanized sheet metal duct runs, registers and grilles, thermostat and electrical hookup, connection to gas line and gas piping, chimney vent and vent accessories, supply and return air plenums, system start-up and balancing.

Costs

This could cost between $4,000-$7,300, not including wall, floor and ceiling patching as required.

A/C installation

The installation of a 5 ton A/C unit added to an existing forced air furnace includes remote condenser and pad, coils and cabinet, refrigeration tubing, new thermostat, electric wiring and connection. This would cost between $5,700-10,000.

Electrical

Service upgrade

The service of older homes is usually inadequate and may need to be updated to 200 Amps. Additionally, if the panel is made by Federal Pacific, then it will most likely also need to be replaced. The installation of a 200 Amp service enclosure will start around $300.

Wiring

Nearly all of the new homes today are wired with non-metallic sheathed cable called Romex, but that may not be what you find when you work on an older house. Depending on its age, you may have some surprises.

Types

Homes built before about 1930 usually had knob and tube (K&T) wiring. Wires were strung between porcelain insulators driven into studs and joists. If wire had to pass through framing, a hollow porcelain tube was inserted in a hole drilled through the stud or joist. Conductors were usually single strands covered with cloth insulation.

Aluminum wire is another type that’s no longer used for interior home electrical systems. Aluminum is a good and durable conductor and is usually less expensive than the more popular copper. In the 1970s they found that aluminum wire was prone to arcing and starting fires at connections.

Sizes

Electrical wire size is measured in American wire gauge (AWG) and usually abbreviated with the pound sign. For example, #14-3 indicates a 14-gauge wire with three conductors (and probably a separate bare ground wire). The smaller the gauge number, the bigger the wire and the greater its current-carrying capacity.

Most circuits in a home are rated at 15 amps and use 14-gauge copper wire. Circuits for kitchen appliances should be rated at 20 amps and use 12-gauge copper wire. Circuits for an electric water heater, air conditioner or electric clothes dryer should be 30 amps and use 10-gauge copper wire. An electric range requires 6-gauge copper wire and a 50-amp breaker. All of these cables should include a copper ground wire.

Costs

For an exposed wall, running 14 gauge Romex can run between $1.40-$4.00/LF. Running conduit can cost between $1.50 and $8.00/LF, depending on diameter.

Receptacles

In most rooms, the code requires that no point along the floor line be more than 6′ from a receptacle. That means you need an outlet at least every 12′ along walls.

Plan on six duplex outlets per 20-amp circuit. Your electrician may suggest ways to put 10 or even 12 outlets on a circuit and still meet NEC requirements. Every room needs either a switch-operated overhead light or a switch-operated outlet. Code requires the switch to be located by the door at the room’s entrance.

Costs

Installing a metal conduit box to contain switches, receptacles, an overhead fixture, or ceiling fan can be between $10-$30 EA installed.

Smoke detectors

Nearly all communities code requires a minimum number and placement of smoke detectors, so you should plan on adding those as needed.

Understanding how to estimate rehab costs accurately only goes so far, if you don’t have emergency funds in place for unexpected repairs. That’s where your rehab costs contingency comes into play.

Rehab Construction Costs Contingency

Understanding how to estimate rehab costs accurately only goes so far, if you don’t have emergency funds in place for unexpected repairs. That’s where your rehab costs contingency comes into play. It is always a smart idea to allocate for unexpected costs, especially in such a variable thing such as home repair.

The rehab construction costs contingency is usually counted as a percentage of estimated rehab costs between 5-25%. This is your risk mitigation plan that is a reflection of the risk inherent to a particular real estate rehab project. That is, if you feel that the project is very risky because there are many unknowns, then your contingency for rehab construction costs should reflect this. You should therefore be very careful to outline every aspect of your renovation plan before calculating this cost.

For example, if you are working on a 100-year old house and you don’t know whether moving a wall is going to require structural reinforcements, or that adding a bathroom will require code updates to the entire plumbing system, then your contingency should reflect this risk and be on the higher end.

You should however, try to be as precise as possible with your construction cost estimates, and remove risks by getting the information required to reduce them. This can be by talking with the building department, or researching your project needs more thoroughly.

Summary

As you can see, estimating costs is a highly variable and complex pursuit. The above guide is a great reference for estimating costs across various common rehab projects. The most important step is perhaps to carefully outline and plan your entire project before you begin, so that you have an idea of what costs will be incurred. Of course, you will get better at this with time and experience, and more familiarity with your local market.

While this wasn’t an exhaustive list of construction costs for rehabbing a property, it should give you an idea on how to start being more precise with estimating rehab costs. REIkit was built using an exhaustive and up-to-date list of thousands of construction cost items, to more easily create your real estate rehab cost estimates.